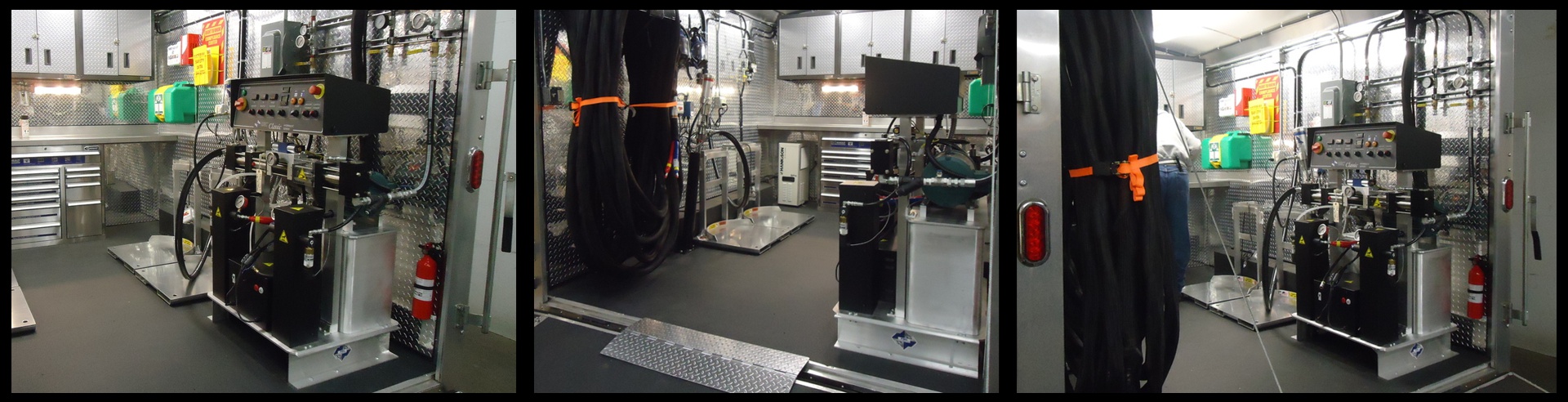

KAMO MOBILE INSULATION RIGS. CUSTOM BUILT TURN-KEY MOBILE INSULATION RIGS AND EQUIPMENT.

PMC engineers a complete product line for Urethane Spray Systems including proportioning units, a uniquely designed heated hose system, transfer pumps, spray guns and the auxiliary equipment required by a contractor to successfully and economically apply residential foam insulation, roofing, pour foam, Polyurea and Polyurea hybrid coatings. Manufactured in the USA, all of PMC’s products are the direct result of customer input, innovation, creativity and the perfectionist spirit of its engineers.

Contact Appalachian today for information and pricing on the complete line of PMC products and accessories.

Call 877-944-7697 for info.

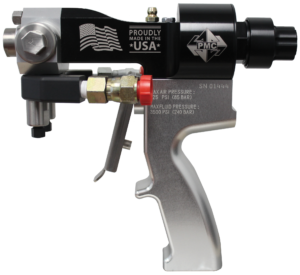

This economically priced gun weighing a mere 2.4 lbs (1.1 kg) is one of the lightest and smallest plural component spray guns on the market today. The Chamber, PCT, Screen Screw Parts, Coupling Block and Check Valves are the same parts used in the proven PMC AP-2 Air Purge Gun.

The AP-3 has fewer parts than the leading competitor. The traditional spool valve method of providing air to move the cylinder has been replaced with a one piece replaceable Cartridge Valve, eliminating the need for multiple O-rings. The short trigger stroke reduces operator fatigue, especially in high triggering applications such as residential insulation. The short trigger stroke also allows precise detail shots that cause competitive guns to struggle. Check valves not only protect against cross-over to the hoses, but PMC has also incorporated a separate check valve to protect the air passages of the gun.

The Advanced Pattern Development and Mixing is accomplished with the unique Chamber/PCT design which provides a multitude of spray pattern and mixing combinations. Chambers are available in all common and half sizes. The hardened PCT’s are available in Round, Flat, Blaster and Pour Configurations. Simple assembly and disassembly is accomplished by having fewer parts and requiring fewer tools to work on this gun. PMC offers the AP-3 with an optional Steel Gun Block.

Offering the “Most Affordable Hydraulic Proportioner with Horizontal Pumps”

Includes Pressure Balance Control System, Inlet Monitoring and Count Down Shutoff

| MODEL | AP-3 |

|

Weight (w/o coupling block)

|

2.4 lbs (1.1 kg)

|

|

Weight (w/coupling block)

|

3.1 lbs (1.4 kg)

|

|

Maximum Working Pressure

|

3,500 psi (240 bar)

|

|

Minimum Air Pressure

|

90 psi (6.2 bar)

|

|

Maximum Air Pressure

|

125 psi (8.6 bar)

|

|

Maximum Output

|

50 lbs/min (22.7 kg)

|

|

Minimum Output

|

3.3 lbs/min (1.5 kg)

|

|

Dimensions

|

7.5”L x 3.3”W x 6.6”H

(19cm x 8.4cm x 17cm)

|

Call 877-944-7697 for info.

Reach NEW HEIGHTS with the new PMC Spray System

- Excellent for Coatings and Foam

- On and Off the Job Safer and Faster

- Minimize the Use of Ladders and Scaffolding

- Less Bending for Spraying the Bottom of the Stud Walls

- Eliminate Blow Back onto Face Shield and Body

- Ideal for Use on Certain Special Roofing

Applications - Easily Spray a 10’ Stud Wall

- Get Inside Rim Joists Safely

- Ideal for Catherdral Ceilings

- Spray overheads Easily

- Adjustable Head

| MODEL | AP-EX |

|

Maximum Working Pressure

|

3,500 psi (245 bar) |

|

Air Pressure

|

90-125 psi

(6.2-8.6 bar) |

|

Maximum Output (1:1 ratio)

|

50 lb/min

(20 L/min) |

|

Minimum Output (1:1 ratio)

|

3.3 lb/min

(1.55 L/min) |

|

Opening Force @ 110 psi (8 Bar)

|

200 lb (91 kg)

|

|

Closing Force @ 110 psi (8 Bar)

|

200 lb (91 kg)

|

|

Weight (with coupling block)

|

8.25 lbs (3.74 kg)

|

|

Weight (without coupling block)

|

7.56 lbs (3.43 kg)

|